Our Products

Tangho Green Pellets

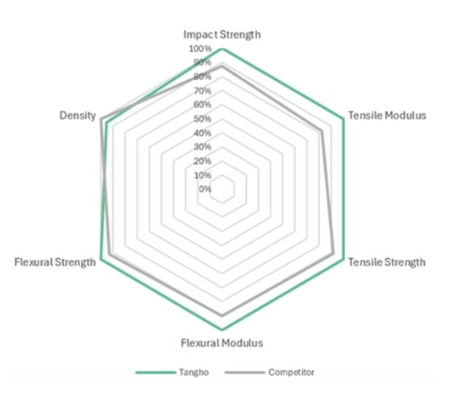

Our Tangho Green Pellets offer a high-performance solution to enhance the properties of plastics in industrial applications. By replacing non-sustainable materials such as fiberglass, carbonate, and talc, and reducing polypropylene content, they deliver rigidity, lightweight characteristics, and strength. These pellets also provide an efficient, drop-in solution for manufacturing processes.

- Sustainable material does not compete with food

- Applications in materials engineering automotive, furniture, household appliances

- Significant Increase in mechanical properties high flexural and tensile modulus

- Excellent dispersion and distribution low moisture

- Lower logistics cost fiber bulk density: 100-300 kg/m3. Pellet bulk density: 500-700 kg/m3

- Recyclability Tangho composites made with hemp pellets can undergo recycling 4 to 6 times before experiencing a decline in mechanical performance.

Comparative Data

The table presents the properties of Tangho hemp-filled composites utilizing the same polypropylene and additives.| Properties/Weight (%) | Values | Units | Method | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Pure PP | 20% GF | 30% GF | 10% HF 10% GF | 15% HF 15% GF | 15% HF 15% GF 5% PPCo | ||||

| Tensile | Modulus | 1310 | 4000 | 5000 | 3690 | 4364 | 4690 | MPa | ASTM D638 |

| Strength | 26.5 | 38.0 | 40.0 | 35.9 | 39.8 | 42.0 | MPa | ASTM D638 | |

| Elongation at break | 28.8 | 7.1 | 6.9 | 7.5 | 7.2 | 7.0 | % | ASTM D638 | |

| Flexural | Modulus | 1380 | 4450 | 5400 | 3850 | 4648 | 4820 | MPa | ASTM D790 |

| Strength | 38.1 | 85.5 | 97.2 | 55.2 | 74.5 | 74.5 | MPa | ASTM D790 | |

| Impact, Izod | Notched, 23°C | 18.2 | 21.5 | 25.0 | 16.0 | 17.3 | 21.8 | J/m | ASTM D256 |

| Density | 0.90 | 1.08 | 1.21 | 0.99 | 1.05 | 1.05 | g/cm³ | ASTM D792 | |

26.5%

reduction in carbon footprint by incorporating 30% hemp fibers into polypropylene composite material compared to pure PP.GreenWall Packing

Our nanocellulose-based GreenWall is a high-quality, biodegradable, and recyclable solution developed through a proprietary process. It enhances strength and barrier properties against CO2, O2, fats, oils, and gases by reducing permeability at the nanoscale. Custom-made and produced through mechanical processes, it is free from chemicals. This material can replace unsustainable alternatives such as nylon, glass, metal, EVOH, fluorine, PVDC, varnishes, and others. Additionally, it improves mechanical properties in various applications. This product is ideal for use in the plastic and paper industries.

NanoPaper

Our NanoPaper, made from industrial hemp nanocellulose, offers dispersed and consistent films with high mechanical strength, flexibility, and excellent energy conductivity. It is ideal for electronics and energy devices applications. It replaces plastics, heavy metals, and harmful chemical compounds, providing a sustainable and high-performance solution compared to traditional methods that may cause non-homogeneous aggregation.